Wire strength test configurations for optimum accuracy

Solution

- Software-controlled force tester and software

- Specialist-sourced capstan and standard wedge grips

Benefits

- Test solution able to handle high loads in all applications

- Bespoke software routines deployed in multiple locations to guarantee consistent, repeatable testing

- Confidence the internal processes are optimised to meet the highest quality and safety requirements

Prior to Mecmesin we would have tied the wire rope in a choke knot to perform the test, but now with the rope grips we are able to test more accurately the performance of the wire rope.

Thomas Reynolds, Testing Manager

Gripple Ltd.

Requirement

Gripple Ltd. design and manufacture fabricated metal products used extensively in the Building Services, Agriculture, Civil Engineering, Viticulture and Seismic Construction sectors. The company originated through innovation in the field of fasteners for wires—which “grip” and “pull”—and these components feature in award-winning solutions for clamping, seismic bracing, suspension and hanging system applications installed anywhere from schools to supermarkets.

Their quality policy implements checks at every stage of manufacture to ensure that products delivered to the end customer are consistently of the highest quality.

As part of the continuous improvement ethic, the Quality and Design Department wanted to review their in-house methods and re-evaluate the test procedures for measuring break loads in their cable components. Gripple’s wire rope fastening systems are engineered to achieve a minimum load rating which, if exceeded, creates a break in the rope as the failure mode. A 5:1 safe working load (SWL) safety factor is adhered to and the test system must cater for wire specimens in the range of 1.5 — 6 mm diameter.

Solutions

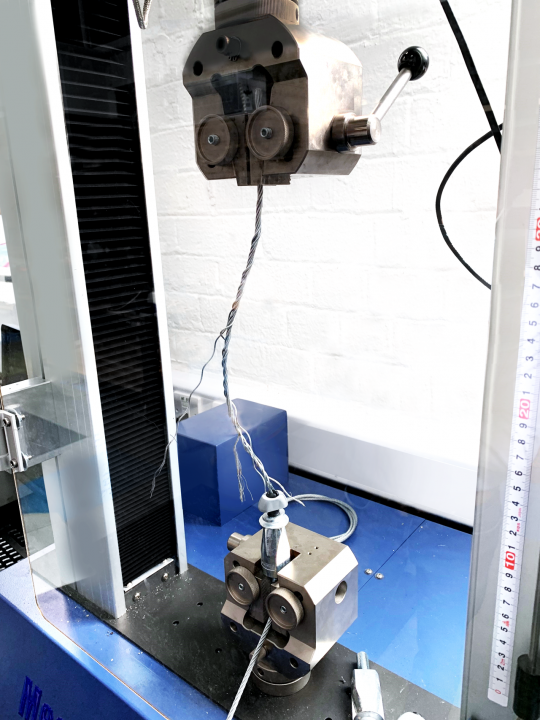

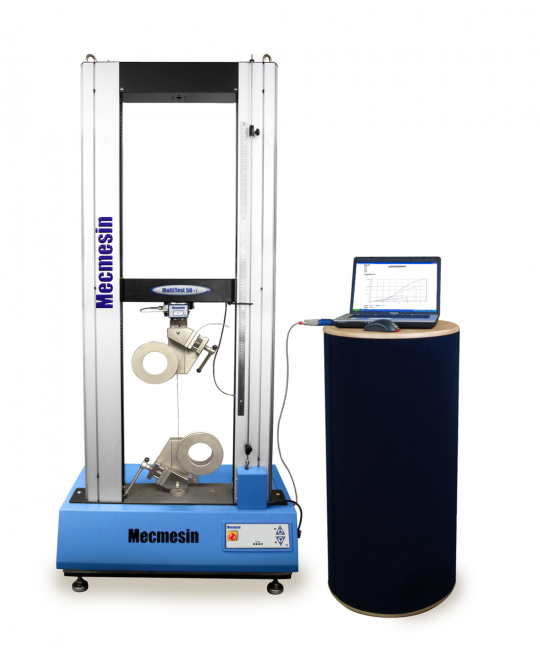

Mecmesin supplied a software-controlled MultiTest 50-i twin-column tensometer with lever-action wedge grips and specialist capstan rope grips; all rated to 50 kN. Previous test procedures had secured the test specimen to the fixture by means of a choke knot, which had proved generally effective. However, with some configurations of wire gauge it had become the point of failure. In order to remove this variability, back-to-back comparison tests were performed with combinations of the available grips:

- Two wedge grips; upper wedge grip clamped the bale, lower wedge grip held the choke knot.

- A hybrid set-up; capstan rope grip as the upper grip, lower wedge grip held the choke knot.

- Two capstan rope grips; upper and lower grips secured both the bale and choke knot.

One test per wire size per configuration was performed at a constant rate of extension of 100 mm/min, running until the Emperor software detected a break. The peak force was recorded and the specimen checked to ensure that the failure was not attributable to local stresses at the grip, slippage inside the grips or any other invalid failure mode.

It was found that Configuration 1 produced valid results only on products up to 3 mm gauge, above which slippage in the upper grip occurred. Configuration 2 successfully handled larger diameter samples, however the knot could cause the failure at lower non-representative loads. Configuration 3, comprising the pair of specifically-designed capstan rope grips, performed consistently across all specimens, returning accurate and repeatable results; thus meeting the high standards set by Gripple.

The company understood the importance not only of the choice of correct testing equipment, but also the best way in which to configure and implement a system. This proved essential in creating the optimum internal test procedures to guarantee thorough QC for its own customers.

As Gripple needed to deploy test equipment in all other global manufacturing locations, the Mecmesin system provided flexible software licensing for easy exchange of test programs and test results. This ensured exactly the same test routines and best practice standards could be efficiently shared amongst all sites, making data comparison seamless.

Test equipment