Tensile testing leather to international standards (ISO) for strength, elongation and tear resistance methods

Solution

- Software-controlled motor-driven tensile tester

- Specific fixtures to grip leather, designed to ISO recommendations

Benefits

- Flexible programming environment to implement test standard methods

- Fixtures available for complete suite of test routines, quick-change

- Multiple tests able to be performed on one machine quickly and efficiently

Requirement

One of Russia's largest tanners, Russkaya Kozha based in Ryazan near Moscow, consulted Mecmesin as they wished to perform tensile tests on their leather materials in accordance with a number of international ISO standards.

As one of the largest leather suppliers in Europe they produce over 35% of all of Russian finished leather, used for the manufacture of garments, footwear, furniture leathers and automotive upholstery. Hides in the tannery are cured, processed and dyed. As both semi-processed and fully finished materials they must be reliably tested to meet the stringent quality standards expected by customers.

Choosing a suitable tensile tester, with the versatility to perform the various tests quickly and easily in the quality-control laboratory, was a key requirement for Russkaya Kozha.

Solutions

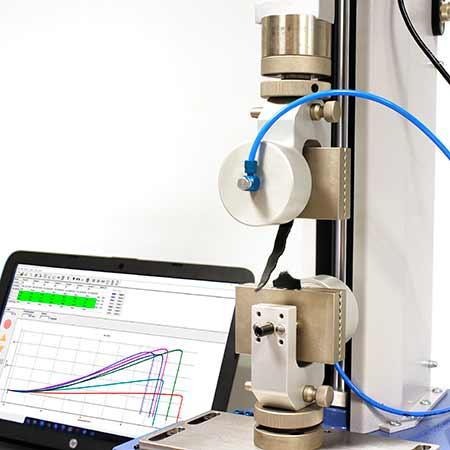

Mecmesin’s distributor worked in close collaboration to supply a MultiTest-i tensile tester with software programs adapted to the methods described in the ISO standards. Test fixtures and grips were developed using quick-change adaptors, so that operators had the minimum changeover time when moving from one test method to the next.

The key test standards covered are ISO 3377-2, ISO 23910 and ISO 3376.

ISO 3377-2: A method for determining the tear strength of leather using a double-edged tear (sometimes described as the Baumann tear test).

A pair of upturned holders were produced to insert inside a horizontal slit within the leather specimen. The upturned holders were then pulled apart by the MultiTest-i tensile tester at 100 mm/min with its software recording the mean tear load in newtons.

ISO 23910: A method for determining the stitch tear resistance of leather.

A metal mandrel was produced to insert inside a vertical slit within the leather specimen. The lower portion of the leather was held in a pneumatic grip with a wave-form profile jaw. The mandrel was then pulled upwards by the MultiTest-i tensile tester at mm/min with its software recording the maximum force in newtons.

ISO 3376: A method for determining the tensile strength, elongation at a specified load and/or break of leather.

The leather specimen is cut to a ‘dogbone’ shape, so that it is narrower in the portion between the grips and will therefore break in this region. Each wider end of the specimen is held in a pneumatic grip with wave-form jaws. The jaws are set at an initial distance of 50 mm apart and then pulled by the MultiTest-i tensile tester at 100 mm/min with its software recording the force and elongation as the leather is stretched.

The tensile strength and elongation at break are automatically calculated by the software for inclusion in a test report configured to Russkaya Kozha’s requirements.

Test equipment